Printer rip curve how to#

To manage the entire workspace, we have hired an adroit and skilled workforce, which is able to fulfill clients’ demands in an efficient way by putting in its best efforts. How to edit Dot Gain curves and Grey Balance.

Printer rip curve driver#

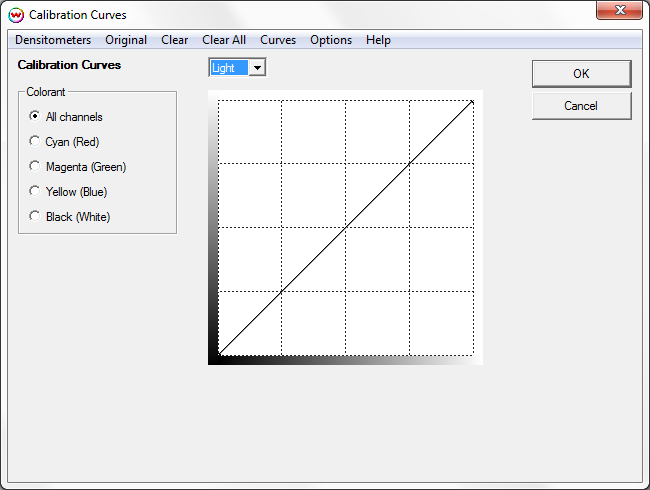

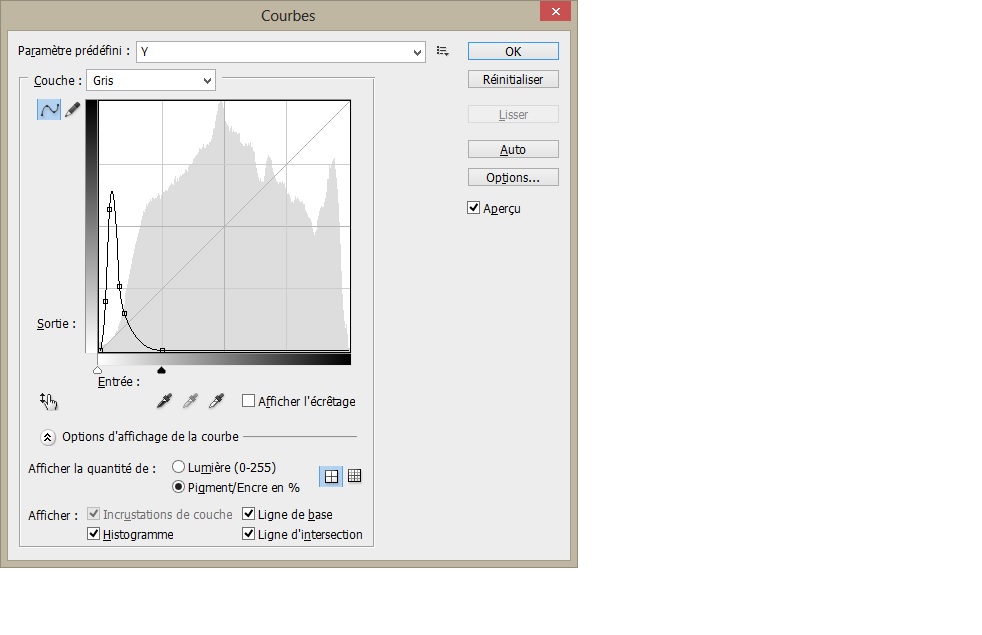

driver or RIP) settings or press adjustments (CTP tone curves, ink weights etc.) are chosen properly often this ideal machine state is reached as a result of a process of step-by-step testing of various options.

We are backed by a spacious warehouse that includes latest machines based on modern technology to arrange and maintain bulk quantities of products in a safe manner. VinylMaster Xpt 4.0: VinylMaster Xpt is dedicated software for: - Designing Super High Quality Artwork - Providing You with the most Powerful Suite of Design. Its vitally important at this stage that either the printer control software (i.e. It is really, really expensive and it's not a RIP, but it could potentially help you out. I have worked a little with Fiery Central. To attain maximum client satisfaction is the sole aim and core motto of our company and we always fulfill it with our ethical business practices. While it's an excellent RIP and is great for workflow and job management, it won't necessarily improve your screening on the 1250 even though it has a custom gradation/curve tool. Warm and cool split-tone, change black ink for matte or gloss printing, can also print digital negatives. Use 7900-9900-PiezoDN curve folder for digital negatives with this ink set. We are migrating people over to the more adaptable P2/K6 configurations. We have been able to prove our commitment towards providing complete customer satisfaction by offering excellent quality products and services with the aid of our transparent business approach. We are not publishing K7 curves for this printer combo. Under this, we offer UV Flatbed Printing machine, Eco Solvent Printing machine, Flex Printing Machines, Vinyl Sticker Cutting Plotters and Laser Cutting & Engraving machine. The purpose of a RIP is to increase productivity in terms of control, scheduling, and speed by removing time and memory-intensive image printing tasks from a PC or workstation to a dedicated processor. Moreover, we render services regarding Repair and Maintenance for the printing machines made available by us. RIPs are typically third-party solutions used in conjunction with printers and large-format printers.

We, Third Eye Technologies, established in the year 2005, are one of the distinguished manufacturer, importer and supplier for wide range of Signage printing machines, sticker cutting plotters, laser cutting and engraving machines.

0 kommentar(er)

0 kommentar(er)